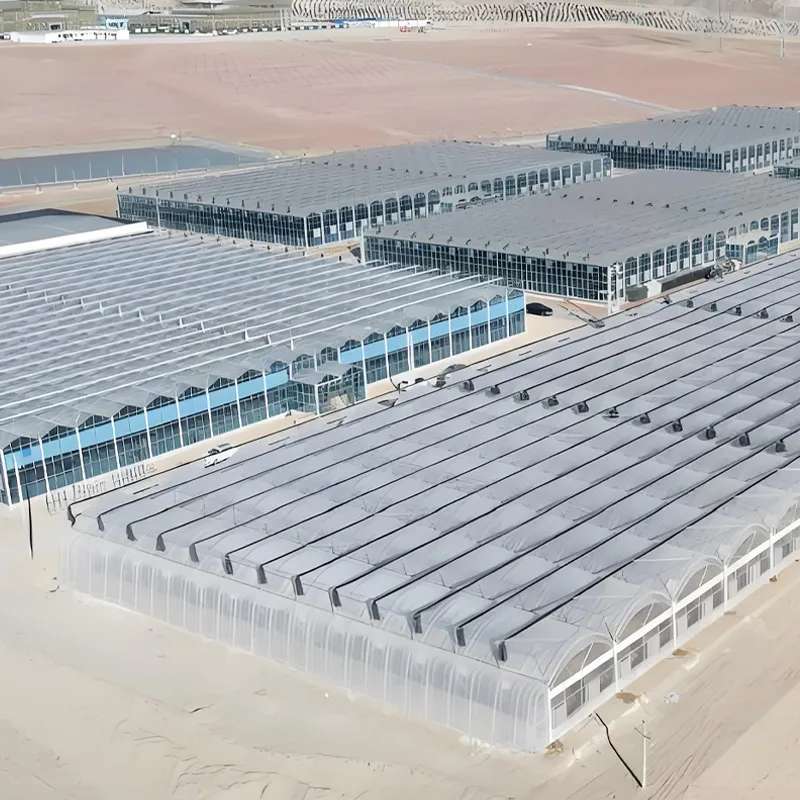

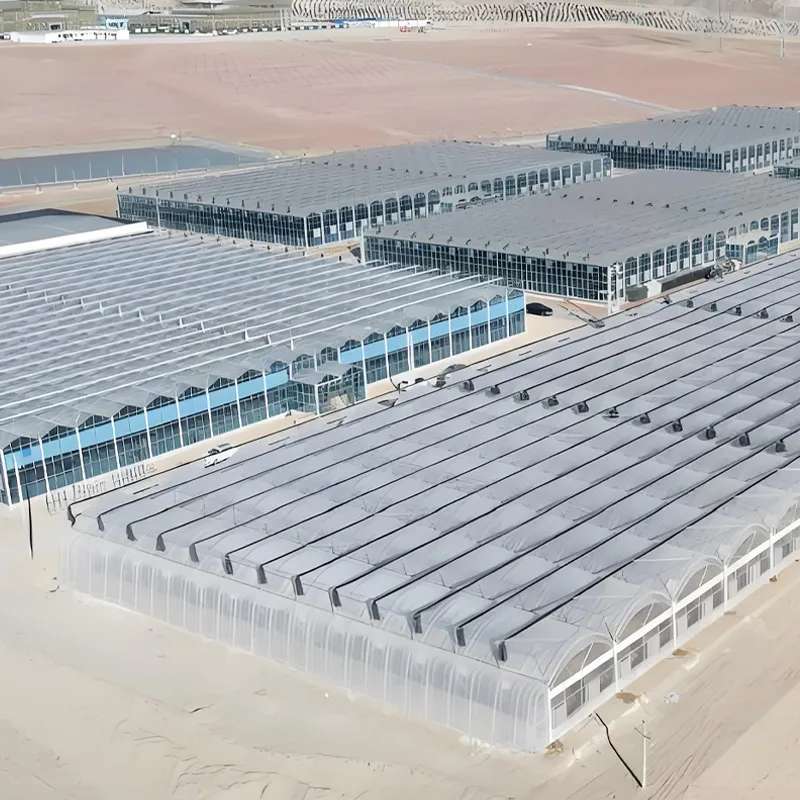

Fruit Planting System One-Stop Solution

Introduction:

Type:Venlo/Arch/Tunnel/Sawtooth/Customized

Structure:Q235 grade hot-dip galvanized steel pipes, service life of 15-20 years

Covering Materials:Glass/Polycarbonate/Plastic Film/Customized

Optional system:Shading system,ventilation system,insulation quilt system,heating system,cooling system,growing system,irrigation&fertilizer system,water tank,smart control system,crops hanging system

Type:Venlo/Arch/Tunnel/Sawtooth/Customized

Structure:Q235 grade hot-dip galvanized steel pipes, service life of 15-20 years

Covering Materials:Glass/Polycarbonate/Plastic Film/Customized

Optional system:Shading system,ventilation system,insulation quilt system,heating system,cooling system,growing system,irrigation&fertilizer system,water tank,smart control system,crops hanging system

Planting system:

Planting models:metal gutter/plastic gutter/pot/dutch bucket

Planting substrate:coco peat growing bags/Coco peat pieces

Planting crop:Strawberry/Blueberry/Raspberry

|

|

|

|

Coco peat metal gutte Coco peat metal gutte |

Coco peat metal gutte Coco peat metal gutte |

Coco peat pot growing Coco peat pot growing |

Coco peat pot growing Coco peat pot growing |

Water Fertilizer&Irrigation System:

Water fertilizer integrated machine

1.Introduction:

a. Intelligent irrigation with water and fertilizer integration utilizes a water pressure system to add soluble solid or liquid fertilizers into the fertilizer tank and then irrigate. The automatic fertilizer application machine precisely mixes the fertilizer, applies it evenly, and does so at fixed times and in fixed quantities, allowing for the maximum utilization of water, fertilizer and energy.

b. 7-inch touch screen, fully Chinese-based human-computer interaction system, featuring data acquisition, equipment control, and remote access functions. It can be controlled manually or via the APP.

c. Thickened aluminum alloy support, sturdy and durable, resistant to corrosion, serving the functions of fixation, support and stability.

2.Parameter:

Model: XLH-YL2

Voltage: 220V/380V/Customized

Power: 2.2KW + 4KW

Liquid flow detection: EC sensor, PH sensor

Number of channels: Five channels

Fertilizer intake rate: 15m³/h (variable frequency constant pressure)

Valve control quantity: 16 (expandable)

Touch screen: 10 inches

Control method: Machine / Mobile APP

|

|

Irrigation system:

Application:

Agricultural production: All crops such as grains, vegetables, fruit trees, tea gardens, etc.

Landscaping and greening: Residential area greening, lawns, flower gardens.

Greenhouses and sheds: Meeting high humidity requirements, regulating temperature and humidity.

Special environments: Sloping land, soil with strong or weak permeability.

Type:

Drip irrigation: Water and fertilizer are delivered drop by drop to the roots, saving water, with good water retention effect, suitable for areas with water shortage.

Sprinkler irrigation: Simulates rainfall, suitable for sloping land, uneven land, adjustable spraying intensity.

Micro-sprinkler irrigation: Fine spraying, used in greenhouses, flowers, can lower temperature and increase humidity

PE irrigation pipe PE irrigation pipe |

Drip irrigation belt Drip irrigation belt |

Drip arrow Drip arrow |

Accessories Accessories |

Field drip irrigation Field drip irrigation |

Hanging irrigation Hanging irrigation |

Spray irrigation Spray irrigation |

|

Water Treatment Equipment:

Comprise:Backwash Disc filter+Sand Media Filter +RO water treatment system

Backwash Disc filter

1.Introduction:

Automatic disc filter system with disc filtering element(as below) with 2"/ 3" /4" backwash valves,air valve,manifolds,controller.

Easy to install. Automation available in 220V(110V or battery).Automatic disc filter as fine filtration, protection tape irrigation system from blockage.Used as the second level filtration to effectively remove fibrous impurities, having a high ability to catch soft impurities.

The available flow rate is from 10m3/h to 1500m3/h.

2.Characteristics:

1. Filtration precision: 130 micron standard in irrigation.(20-400 micron)

2. Pipe Material: carbon steel / Plastic with good antiseptic effect

3. Filter units: Strengthen nylon(PA)

4. Space: Small with large flow rate

5. Backwash: Automatic and the water supply won't stop when back flushing

6. Water consumption: Less than 1% of filtering water,pressure loss don't over 0.02 M pa

7. Customized service: Pressure,material and power if there are specialized requirements,welcome to contact us

Sand Media Filter:

1. Introduction:

Sand filter system includes tanks with under drain system, backwash valve, piping, and automatic control system.

DMF filters are designed for the most challenging dirty water conditions, with a high-performance solution for water filtration down to 20 microns. These durable carbon steel filters utilize a 24"-54" vertical side shell depth for the removal of organic and inorganic suspended solids for filtering large volumes of water with very little pressure drop and a long-term value.

2.Application:

Commercial - Golf course and sporting field irrigation systems.

Industrial - Pre-preteatment of UF/RO and wastewater recycling.

Irrigation - Primary filtration for the prevention of blockages in the irrigation system

HVAC- cooling tower side filtration and full system

Metal Processing Plants - Filtration for water cooling and spray nozzles.

Mining - Cleaning of process and waste water.

3.Parameters:

Min. pressure: 0.15Mpa

Max. pressure: 1.0Mpa

Working temperature: <65ºC

Tank thickness: 4/6/8 mm

Power: 220V/110V/battery

RO water treatment system:

1. Introduction:

a. Reverse Osmosis is a technology that is widely used to remove a large majority of contaminants from water by pushing the water under pressure through a semi-permable membrane.It apply to food and beverage, drinking water sectors; Chemical & Pharmaceutical industries;Cosmetics; Electronic components manufacturing.Outlet Flow 0.5t,1t,2t,3t or by customized.

b. Working Flowchart Raw water → original water tank → original water pump → multi-media filter (quartz sand filter)→ activated carbon filter → soft water processor → precision filter → high pressure pump → first stage reverse osmosis (RO) device → pure water tank → high pressure pump → second stage reverse osmosis → ultraviolet sterilization device → water point

2. Feed Water Parameters:

Silt density index(SDI) 15<5

Turbidity <1.0NTU

Organic matter content <1.5

Free residual chlorine polyamide composite membrane <0.1mg/L

Operating temperature 4℃~45℃ for composite membrane

Residual chlorine content <0.1mg/L

Iron content Fe<0.05 when dissolved oxygen >5mg/L

Silicon dioxide content SIO2 <100

Water tank:

1.Introduction:

Our Corrugated Steel Water Tank, also known as a Galvanized Steel Water Storage Tank, is a modular, round above-ground water reservoir made from hot-dip galvanized corrugated steel sheets and a high-strength PVC liner.

2.Application:

Agricultural irrigation &farm water storage

Livestock&poultry farming water supply

Firefighting&emergency water storage

Drinking water &domestic water storage

Rainwater harvesting &water recapturing systems

3.Characteristics:

Durable galvanized steel structure

High-strength PVC liner &reliable waterproofing

Excellent weather,UV&cold resistance

Long service life&cost-effective

Easy maintenance&simple cleaning

Climate Control System:

It can control and regulation of various factors such as temperature, humidity, light, and CO2 in the greenhouse

Intelligent Control Center with distribution cabinet using Siemens PLC, 10--inch touch screen, PROFINET intelligent master station, and optional 5G Internet of Things module. The system supports high-level language programming and can support network communications such as EtherNet, Profibus, and Interbus. It automatic control ventilation system,shading system,insulation quilt system,water pump,fans.

Planting system:

Planting models:metal gutter/plastic gutter/pot/dutch bucket

Planting substrate:coco peat growing bags/Coco peat pieces

Planting crop:Strawberry/Blueberry/Raspberry

|

|

|

|

Coco peat metal gutte Coco peat metal gutte |

Coco peat metal gutte Coco peat metal gutte |

Coco peat pot growing Coco peat pot growing |

Coco peat pot growing Coco peat pot growing |

Water Fertilizer&Irrigation System:

Water fertilizer integrated machine

1.Introduction:

a. Intelligent irrigation with water and fertilizer integration utilizes a water pressure system to add soluble solid or liquid fertilizers into the fertilizer tank and then irrigate. The automatic fertilizer application machine precisely mixes the fertilizer, applies it evenly, and does so at fixed times and in fixed quantities, allowing for the maximum utilization of water, fertilizer and energy.

b. 7-inch touch screen, fully Chinese-based human-computer interaction system, featuring data acquisition, equipment control, and remote access functions. It can be controlled manually or via the APP.

c. Thickened aluminum alloy support, sturdy and durable, resistant to corrosion, serving the functions of fixation, support and stability.

2.Parameter:

Model: XLH-YL2

Voltage: 220V/380V/Customized

Power: 2.2KW + 4KW

Liquid flow detection: EC sensor, PH sensor

Number of channels: Five channels

Fertilizer intake rate: 15m³/h (variable frequency constant pressure)

Valve control quantity: 16 (expandable)

Touch screen: 10 inches

Control method: Machine / Mobile APP

|

|

Irrigation system:

Application:

Agricultural production: All crops such as grains, vegetables, fruit trees, tea gardens, etc.

Landscaping and greening: Residential area greening, lawns, flower gardens.

Greenhouses and sheds: Meeting high humidity requirements, regulating temperature and humidity.

Special environments: Sloping land, soil with strong or weak permeability.

Type:

Drip irrigation: Water and fertilizer are delivered drop by drop to the roots, saving water, with good water retention effect, suitable for areas with water shortage.

Sprinkler irrigation: Simulates rainfall, suitable for sloping land, uneven land, adjustable spraying intensity.

Micro-sprinkler irrigation: Fine spraying, used in greenhouses, flowers, can lower temperature and increase humidity

PE irrigation pipe PE irrigation pipe |

Drip irrigation belt Drip irrigation belt |

Drip arrow Drip arrow |

Accessories Accessories |

Field drip irrigation Field drip irrigation |

Hanging irrigation Hanging irrigation |

Spray irrigation Spray irrigation |

|

Water Treatment Equipment:

Comprise:Backwash Disc filter+Sand Media Filter +RO water treatment system

Backwash Disc filter

1.Introduction:

Automatic disc filter system with disc filtering element(as below) with 2"/ 3" /4" backwash valves,air valve,manifolds,controller.

Easy to install. Automation available in 220V(110V or battery).Automatic disc filter as fine filtration, protection tape irrigation system from blockage.Used as the second level filtration to effectively remove fibrous impurities, having a high ability to catch soft impurities.

The available flow rate is from 10m3/h to 1500m3/h.

2.Characteristics:

1. Filtration precision: 130 micron standard in irrigation.(20-400 micron)

2. Pipe Material: carbon steel / Plastic with good antiseptic effect

3. Filter units: Strengthen nylon(PA)

4. Space: Small with large flow rate

5. Backwash: Automatic and the water supply won't stop when back flushing

6. Water consumption: Less than 1% of filtering water,pressure loss don't over 0.02 M pa

7. Customized service: Pressure,material and power if there are specialized requirements,welcome to contact us

Sand Media Filter:

1. Introduction:

Sand filter system includes tanks with under drain system, backwash valve, piping, and automatic control system.

DMF filters are designed for the most challenging dirty water conditions, with a high-performance solution for water filtration down to 20 microns. These durable carbon steel filters utilize a 24"-54" vertical side shell depth for the removal of organic and inorganic suspended solids for filtering large volumes of water with very little pressure drop and a long-term value.

2.Application:

Commercial - Golf course and sporting field irrigation systems.

Industrial - Pre-preteatment of UF/RO and wastewater recycling.

Irrigation - Primary filtration for the prevention of blockages in the irrigation system

HVAC- cooling tower side filtration and full system

Metal Processing Plants - Filtration for water cooling and spray nozzles.

Mining - Cleaning of process and waste water.

3.Parameters:

Min. pressure: 0.15Mpa

Max. pressure: 1.0Mpa

Working temperature: <65ºC

Tank thickness: 4/6/8 mm

Power: 220V/110V/battery

RO water treatment system:

1. Introduction:

a. Reverse Osmosis is a technology that is widely used to remove a large majority of contaminants from water by pushing the water under pressure through a semi-permable membrane.It apply to food and beverage, drinking water sectors; Chemical & Pharmaceutical industries;Cosmetics; Electronic components manufacturing.Outlet Flow 0.5t,1t,2t,3t or by customized.

b. Working Flowchart Raw water → original water tank → original water pump → multi-media filter (quartz sand filter)→ activated carbon filter → soft water processor → precision filter → high pressure pump → first stage reverse osmosis (RO) device → pure water tank → high pressure pump → second stage reverse osmosis → ultraviolet sterilization device → water point

2. Feed Water Parameters:

Silt density index(SDI) 15<5

Turbidity <1.0NTU

Organic matter content <1.5

Free residual chlorine polyamide composite membrane <0.1mg/L

Operating temperature 4℃~45℃ for composite membrane

Residual chlorine content <0.1mg/L

Iron content Fe<0.05 when dissolved oxygen >5mg/L

Silicon dioxide content SIO2 <100

Water tank:

1.Introduction:

Our Corrugated Steel Water Tank, also known as a Galvanized Steel Water Storage Tank, is a modular, round above-ground water reservoir made from hot-dip galvanized corrugated steel sheets and a high-strength PVC liner.

2.Application:

Agricultural irrigation &farm water storage

Livestock&poultry farming water supply

Firefighting&emergency water storage

Drinking water &domestic water storage

Rainwater harvesting &water recapturing systems

3.Characteristics:

Durable galvanized steel structure

High-strength PVC liner &reliable waterproofing

Excellent weather,UV&cold resistance

Long service life&cost-effective

Easy maintenance&simple cleaning

Climate Control System:

It can control and regulation of various factors such as temperature, humidity, light, and CO2 in the greenhouse

Intelligent Control Center with distribution cabinet using Siemens PLC, 10--inch touch screen, PROFINET intelligent master station, and optional 5G Internet of Things module. The system supports high-level language programming and can support network communications such as EtherNet, Profibus, and Interbus. It automatic control ventilation system,shading system,insulation quilt system,water pump,fans.